Since our first steps into the world of mass produced Ready To Run models for the Queensland market back in 2012, we’ve had a small mountain of emails, messages and phone calls regarding “how it’s done” and things of that nature.

Since our first steps into the world of mass produced Ready To Run models for the Queensland market back in 2012, we’ve had a small mountain of emails, messages and phone calls regarding “how it’s done” and things of that nature.

At the same time, we’ve heard lots of misleading information from people based on how they believe these models are made or from companies blaming “the Chinese” or “the Factory” for their problems. We’d like to set that straight.

At the same time, we’ve heard lots of misleading information from people based on how they believe these models are made or from companies blaming “the Chinese” or “the Factory” for their problems. We’d like to set that straight.

Hopefully, in this chapter, we’ll explain exactly how the process works and how it differs from the conventional methods used for the production of kits and the like for the Australian model railway market.

Hopefully, in this chapter, we’ll explain exactly how the process works and how it differs from the conventional methods used for the production of kits and the like for the Australian model railway market.

Prior to 2012 Wuiske Models manufactured kits… about 350 of them! All of these kits first began as a master or pattern. The patterns were either a hand made pattern (usually made from styrene) and taking months to produce or they were made from a rapid prototyped pattern.

Prior to 2012 Wuiske Models manufactured kits… about 350 of them! All of these kits first began as a master or pattern. The patterns were either a hand made pattern (usually made from styrene) and taking months to produce or they were made from a rapid prototyped pattern.

The process for rapid prototyping these patterns sped up the process but also meant we could achieve far higher levels of detail because we were no longer limited to what could actually be made by hand.

The process for rapid prototyping these patterns sped up the process but also meant we could achieve far higher levels of detail because we were no longer limited to what could actually be made by hand.

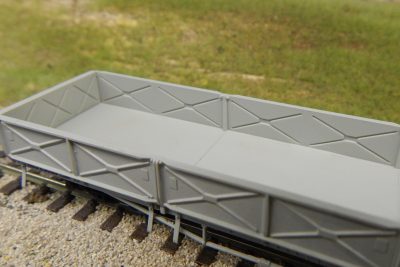

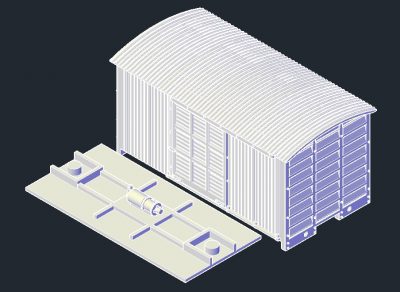

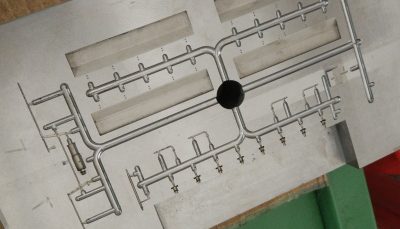

The end result was a pattern being made using the SLS process of printing that produced a very nice model but one that was INCREDIBLY fragile, not to mention expensive (the A wagon pattern here cost around $600 just for the printed pattern). this system worked well and was then sent to our caster to be reproduced in silicone rubber molds.

The end result was a pattern being made using the SLS process of printing that produced a very nice model but one that was INCREDIBLY fragile, not to mention expensive (the A wagon pattern here cost around $600 just for the printed pattern). this system worked well and was then sent to our caster to be reproduced in silicone rubber molds.

The problem with this process is that it is very labour intensive. Each kit takes at least one hour to produce the components. The silicone rubber molds have a very short lifespan of about 20 kits and they are HIGHLY affected by changes in weather. As if that wasn’t bad enough, the urethane material as well as the rubber tend to shrink (or sometimes grow) over time. In other words, you could buy a kit today that is 100mm long and but another one a month or so later and it is 102mm long.

The problem with this process is that it is very labour intensive. Each kit takes at least one hour to produce the components. The silicone rubber molds have a very short lifespan of about 20 kits and they are HIGHLY affected by changes in weather. As if that wasn’t bad enough, the urethane material as well as the rubber tend to shrink (or sometimes grow) over time. In other words, you could buy a kit today that is 100mm long and but another one a month or so later and it is 102mm long.

Enter 2012, where Wuiske models decided to take the plunge and attempt to release the QLX louvre wagon as the first step into RTR Queensland models. The attitude taken was that we would either sink or swim (the project cost not that much less than our house in Jandaowae so if we sank it would have been impressive).

Enter 2012, where Wuiske models decided to take the plunge and attempt to release the QLX louvre wagon as the first step into RTR Queensland models. The attitude taken was that we would either sink or swim (the project cost not that much less than our house in Jandaowae so if we sank it would have been impressive).

In order to produce this model (or any other for that matter), the first step was to identify if it is worthwhile to produce. As an example, how many dining cars do you need? One you say? Well our minimum run is between 1500 and 2500 units. Hopefully this answers why the Lander coaches have not been done… yet.

In order to produce this model (or any other for that matter), the first step was to identify if it is worthwhile to produce. As an example, how many dining cars do you need? One you say? Well our minimum run is between 1500 and 2500 units. Hopefully this answers why the Lander coaches have not been done… yet.

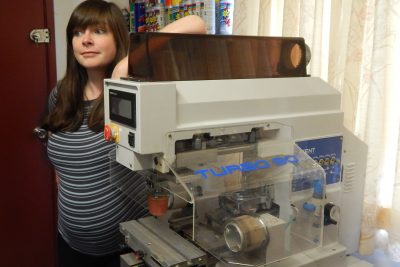

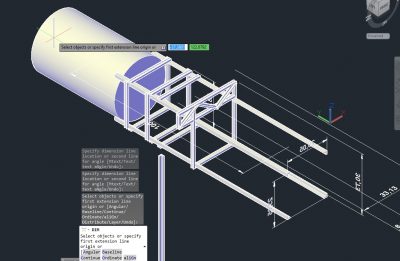

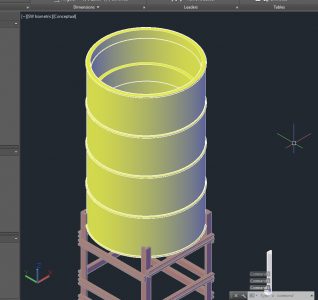

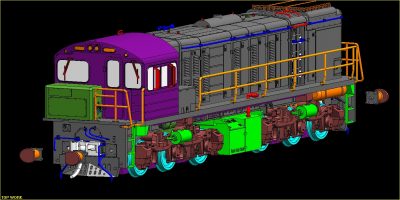

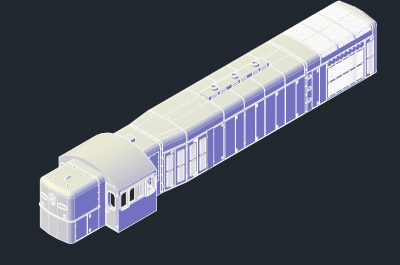

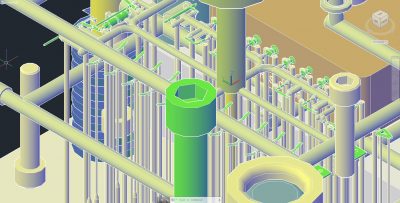

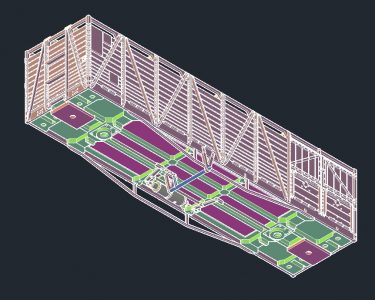

Once the prototype has been chosen, it’s time to start drawing. Most companies outsource this to their factory and pay a few thousand US Dollars for the privilege. Wuiske Models do our own design work in house.

Once the prototype has been chosen, it’s time to start drawing. Most companies outsource this to their factory and pay a few thousand US Dollars for the privilege. Wuiske Models do our own design work in house.

This is simply because we are familiar with the prototype and we can get access to complete plans and the prototype (usually). In other words, we don’t really have many revisions to be made (those things are expensive).

This is simply because we are familiar with the prototype and we can get access to complete plans and the prototype (usually). In other words, we don’t really have many revisions to be made (those things are expensive).

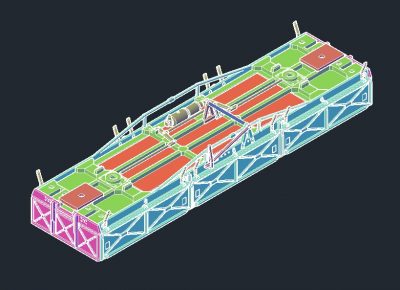

The next step is to discuss the project and the design with the tool maker. They will lay the items out depending on what sort of plastic it needs to be made from or if it would be better made from an etch for instance.

The next step is to discuss the project and the design with the tool maker. They will lay the items out depending on what sort of plastic it needs to be made from or if it would be better made from an etch for instance.

Once this is done, we get a Tooling Drawing… and a bill. A BIG BILL!

Once this is done, we get a Tooling Drawing… and a bill. A BIG BILL!

So, this is crunch time, this is the part where Bridget and I take a very deep breath and part with a large chunk of our collection of modern currency.

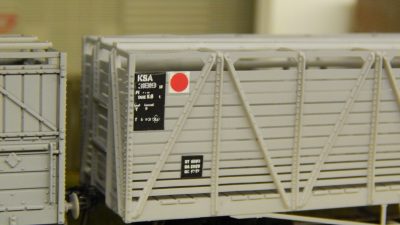

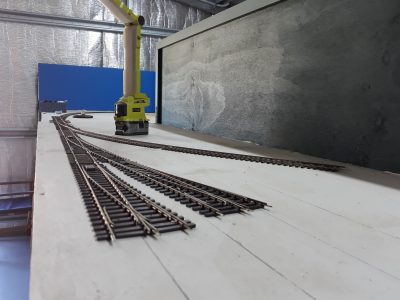

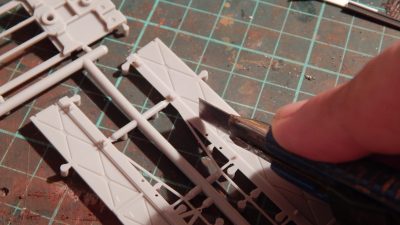

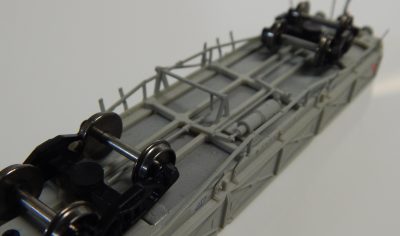

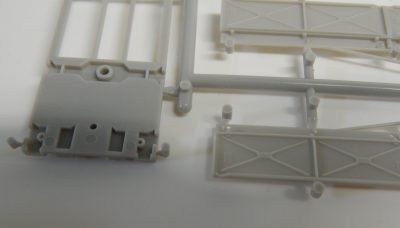

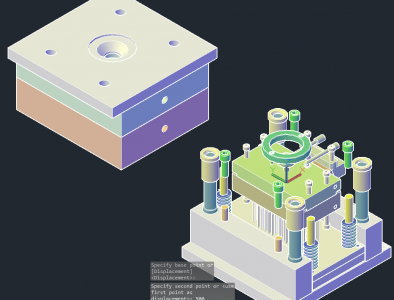

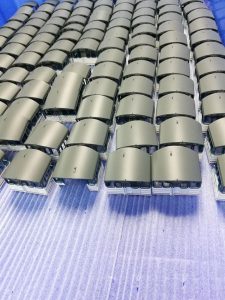

Usually the tooling process will take one to three months. once it’s done, we get a “test shot”. Test shots serve to tell us if there is anything that has been made incorrectly from the drawing (we actually had a bolt head forgotten on one model) and where you can make any changes.

Usually the tooling process will take one to three months. once it’s done, we get a “test shot”. Test shots serve to tell us if there is anything that has been made incorrectly from the drawing (we actually had a bolt head forgotten on one model) and where you can make any changes.

Once we’ve approved the test shots, we get another bill. Another BIG BILL! But we have a working high pressure mold.

Once we’ve approved the test shots, we get another bill. Another BIG BILL! But we have a working high pressure mold.

I feel I should point out the difference between high and low pressure molds here. Low pressure molds are a cheaper alternative (about 1/10th the price) and will give you a mold life of around 1,000 products (this can vary wildly). Where as a high pressure mold will give you a MINIMUM of 300,000 products as well as a severe injury if your foot goes underneath it.

I feel I should point out the difference between high and low pressure molds here. Low pressure molds are a cheaper alternative (about 1/10th the price) and will give you a mold life of around 1,000 products (this can vary wildly). Where as a high pressure mold will give you a MINIMUM of 300,000 products as well as a severe injury if your foot goes underneath it.

Some examples of low pressure molds are things like the Wuiske Models W irons used on our old four wheel wagon kits as well as the Chivers Fineline model kits produced in the 1990s. The reason for going with higher pressure (aside from the mold life) is that you can make MUCH finer and more detailed items when they are injected at 250 tonne of pressure than 2-8 tonne.

Some examples of low pressure molds are things like the Wuiske Models W irons used on our old four wheel wagon kits as well as the Chivers Fineline model kits produced in the 1990s. The reason for going with higher pressure (aside from the mold life) is that you can make MUCH finer and more detailed items when they are injected at 250 tonne of pressure than 2-8 tonne.

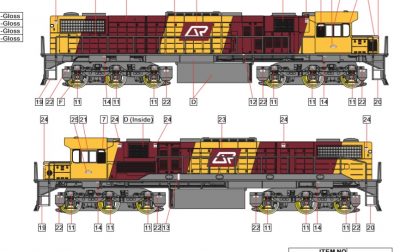

Once we have our molds, the next job is to prepare our artwork designs. This is where the painting and printing is arranged. This means the factory can be one step ahead with all processes.

Once we have our molds, the next job is to prepare our artwork designs. This is where the painting and printing is arranged. This means the factory can be one step ahead with all processes.

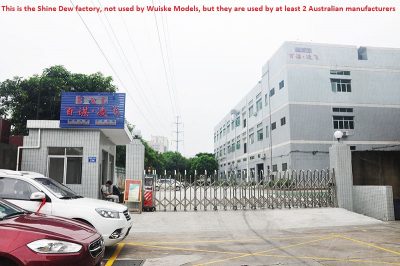

Next, we go into production, this can vary wildly in the time it takes for a run. If the model is being made in China, the production team is usually around 30 woman (they’re far more dexterous than us blokes, deal with it). whilst if we’re producing here in Queensland, our team is between 2 and 8 people depending on the complexity.

Next, we go into production, this can vary wildly in the time it takes for a run. If the model is being made in China, the production team is usually around 30 woman (they’re far more dexterous than us blokes, deal with it). whilst if we’re producing here in Queensland, our team is between 2 and 8 people depending on the complexity.

The next step is packaging and Quality control (universally known as QC). This is most likely the biggest part of the production. This is where you find out someone forgot to put the wheels on a model (it happens when there are thousands of them). With our Chinese made products, we can thank (and he will remind us if we forget to do so) Kieren Haskell. That mad half Aussie, half Ferret that we reluctantly call a mate.

The next step is packaging and Quality control (universally known as QC). This is most likely the biggest part of the production. This is where you find out someone forgot to put the wheels on a model (it happens when there are thousands of them). With our Chinese made products, we can thank (and he will remind us if we forget to do so) Kieren Haskell. That mad half Aussie, half Ferret that we reluctantly call a mate.

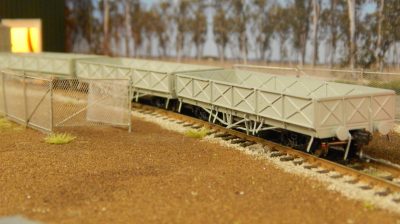

So, now we have a shiny new model to show you. Thousands of shiny new models actually. all we can do is hope like hell that you, the modeller likes them and buy them.

So, now we have a shiny new model to show you. Thousands of shiny new models actually. all we can do is hope like hell that you, the modeller likes them and buy them.

Finally, we can sit back, wipe away the sweat and tears, apologise to our team for that rant I went on each and every evening when we were under the gun and get started on our next project.

Finally, we can sit back, wipe away the sweat and tears, apologise to our team for that rant I went on each and every evening when we were under the gun and get started on our next project.

Over the past 17 years of Wuiske Models we have had products made for us in Queensland, New South Wales, Victoria, South Australia, New Zealand, England, Scotland, India, Taiwan and of course China. In an ideal world, we will eventually be able to make the vast majority of our products right here in Queensland.

Over the past 17 years of Wuiske Models we have had products made for us in Queensland, New South Wales, Victoria, South Australia, New Zealand, England, Scotland, India, Taiwan and of course China. In an ideal world, we will eventually be able to make the vast majority of our products right here in Queensland.

With our chosen profession, Bridget and I know we will never be millionaires, but we’re very happy to be working in an industry we love (most of the time), working with friends (again, most of the time) and dealing with people whom are just as insane and obsessed as we are on a daily basis.

With our chosen profession, Bridget and I know we will never be millionaires, but we’re very happy to be working in an industry we love (most of the time), working with friends (again, most of the time) and dealing with people whom are just as insane and obsessed as we are on a daily basis.

With that being said, both Bridget and I would like to thank each and every member of the Wuiske Models team both here in Australia as well as those around the world whom help us deliver the products we love making. Hopefully this little chapter of ours has helped shed some light on the processes involved in making your models.

With that being said, both Bridget and I would like to thank each and every member of the Wuiske Models team both here in Australia as well as those around the world whom help us deliver the products we love making. Hopefully this little chapter of ours has helped shed some light on the processes involved in making your models.

As mentioned previously, we have some big things coming in 2020 and rest assured we will be working quietly away in the background to bring them to you… As ever, we shall see how we go.

As mentioned previously, we have some big things coming in 2020 and rest assured we will be working quietly away in the background to bring them to you… As ever, we shall see how we go.