So for the third and final part of the parts that partially form the parts of parts to make the larger parts of this series of corners about the Jandowae Grain Complex, let’s finish up with the wheat shed… Or at least part of it?

So for the third and final part of the parts that partially form the parts of parts to make the larger parts of this series of corners about the Jandowae Grain Complex, let’s finish up with the wheat shed… Or at least part of it?

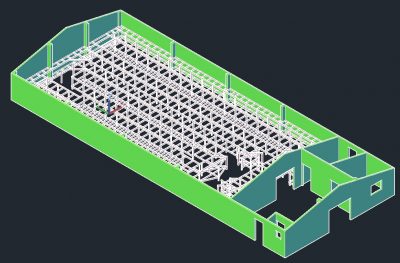

The wheat shed in Jandowae is a VERY normal structure that can be found all over Queensland, with similar versions of it all over Australia.

The wheat shed in Jandowae is a VERY normal structure that can be found all over Queensland, with similar versions of it all over Australia.

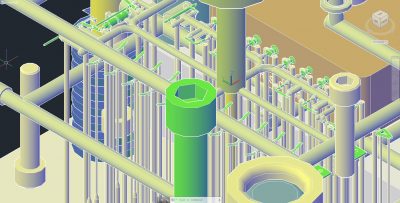

This structure is fairly simple in design but actually presents a vast wealth of details to incorporate into it.

This structure is fairly simple in design but actually presents a vast wealth of details to incorporate into it.

Overall, it’s a shed. Plain and simple. However, with the nature of the products loaded into it, bracing is required externally to ensure the weight of the product doesn’t force the walls out of shape or worse yet, cause them to collapse completely.

Overall, it’s a shed. Plain and simple. However, with the nature of the products loaded into it, bracing is required externally to ensure the weight of the product doesn’t force the walls out of shape or worse yet, cause them to collapse completely.

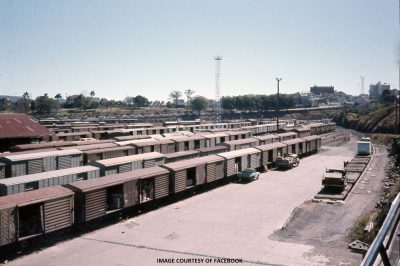

The grain arrive from properties in trucks, B doubles, B triples, double and triple road trains and is unloaded over a simple pit.

The grain arrive from properties in trucks, B doubles, B triples, double and triple road trains and is unloaded over a simple pit.

There are two of these pits on this shed. Both of which are housed in small “lean to” structures on the opposite side of the shed from the railway track.

There are two of these pits on this shed. Both of which are housed in small “lean to” structures on the opposite side of the shed from the railway track.

The pits are very similar to the unloading pits we covered in Chapter 137. Essentially a grate with a small panel over the top of them that gets lifted out of the way and the trucks roll through.

The pits are very similar to the unloading pits we covered in Chapter 137. Essentially a grate with a small panel over the top of them that gets lifted out of the way and the trucks roll through.

As you can most likely tell, these pit structures don’t appear tall enough for a forty foot tipper (thirty eight foot is more common though) to lift fully for unloading.

As you can most likely tell, these pit structures don’t appear tall enough for a forty foot tipper (thirty eight foot is more common though) to lift fully for unloading.

This is where the grain doors come into use. If you look on the back of most tipper trailers used for grain traffic, they have a small grain door located on the rear gate that simply slides upwards, leaving a small opening where the grain can be funneled out.

This is where the grain doors come into use. If you look on the back of most tipper trailers used for grain traffic, they have a small grain door located on the rear gate that simply slides upwards, leaving a small opening where the grain can be funneled out.

This same method is used when a truck is unloading into the small hoppers on a portable auger.

This same method is used when a truck is unloading into the small hoppers on a portable auger.

Along the sides of the shed there are also a multitude of hatches to allow augers to unload into the shed from outside.

Along the sides of the shed there are also a multitude of hatches to allow augers to unload into the shed from outside.

Overall, these sheds are extremely versatile. Mostly, this is due to the sheer volume of additions, revisions and changes made over the years to allow ever changing machinery to be used.

Overall, these sheds are extremely versatile. Mostly, this is due to the sheer volume of additions, revisions and changes made over the years to allow ever changing machinery to be used.

Obviously, all of these changes are geared towards moving ever increasing volumes. This shed in particular, can hold up to 30,000 ton of grain.

Obviously, all of these changes are geared towards moving ever increasing volumes. This shed in particular, can hold up to 30,000 ton of grain.

As a point, on average, that’s around seven trains from just this one structure!

As a point, on average, that’s around seven trains from just this one structure!

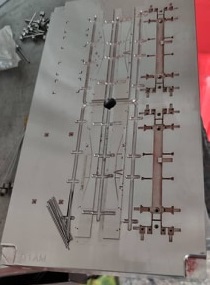

As I mentioned briefly above, the structure is covered with external bracing.

As I mentioned briefly above, the structure is covered with external bracing.

These braces are made from a mixture of three inch and one inch steel pipe.

The lower diagonal brace is two inch pipe, just to be difficult. Some of these structures have angle iron and square RHS used instead but they’re usually newer structures.

The lower diagonal brace is two inch pipe, just to be difficult. Some of these structures have angle iron and square RHS used instead but they’re usually newer structures.

The bracing seems to be around four feet (1200mm) apart and stands around six feet (1800mm) above the ground.

The bracing seems to be around four feet (1200mm) apart and stands around six feet (1800mm) above the ground.

The lower edge of the building is constructed of concrete, some are brick, this is to attempt to limit intrusions from vermin. The concrete course is around two feet (600mm) high.

The lower edge of the building is constructed of concrete, some are brick, this is to attempt to limit intrusions from vermin. The concrete course is around two feet (600mm) high.

The vertical pillars are a folded U channel with the open section facing towards the wall. Simulating this with simple styrene strip would be easy.

The vertical pillars are a folded U channel with the open section facing towards the wall. Simulating this with simple styrene strip would be easy.

The walls are simple corrugated iron up to a height of around eight feet (2400mm) above the ground. There is a second course of corrugated iron above this which extends another six feet (1800mm) above the lower section.

The walls are simple corrugated iron up to a height of around eight feet (2400mm) above the ground. There is a second course of corrugated iron above this which extends another six feet (1800mm) above the lower section.

The bracing along the top section is mounted internally due to the shape of the grain pile inside the shed when full. There is no need for a smooth wall that could be damaged by wheel loaders.

The bracing along the top section is mounted internally due to the shape of the grain pile inside the shed when full. There is no need for a smooth wall that could be damaged by wheel loaders.

To unload the shed, there are two options… The first involves augers being placed inside the shed and being fed with grain by wheel loaders. These access the interior through doors on either end of the building.

To unload the shed, there are two options… The first involves augers being placed inside the shed and being fed with grain by wheel loaders. These access the interior through doors on either end of the building.

The other option is with the augers placed outside the building. The variations seem to depend on whether they’re loading onto rail or truck. With the decline in the Queensland Governments Train Set, trucks are seen in copious quantities at this site.

The other option is with the augers placed outside the building. The variations seem to depend on whether they’re loading onto rail or truck. With the decline in the Queensland Governments Train Set, trucks are seen in copious quantities at this site.

As with the silo complex, the wheat shed is surrounded by conduit, hatches, access doors and electrical panels. The power comes to this structure from an overhead power line running along the dirt road behind the complex.

As with the silo complex, the wheat shed is surrounded by conduit, hatches, access doors and electrical panels. The power comes to this structure from an overhead power line running along the dirt road behind the complex.

Being located in the country, EVERY bit of roofing is seen as a potential water source. As such, there are water tanks and garden sheds (housing the water pumps) located around the structure (complete with a piece of corrugated iron to cover the top).

Being located in the country, EVERY bit of roofing is seen as a potential water source. As such, there are water tanks and garden sheds (housing the water pumps) located around the structure (complete with a piece of corrugated iron to cover the top).

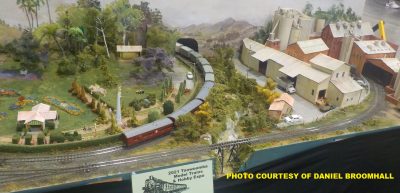

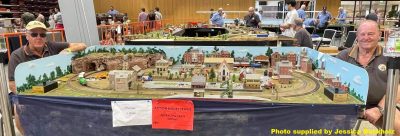

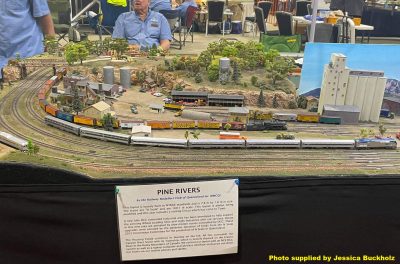

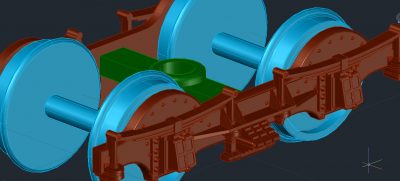

Overall, this structure is my favorite part of the entire complex and has the potential for an insane amount of detail to be added. I’ve seen one modelled (insanely well) by Wayne McDade on his HOn3½ layout and it inspired me to do the same.

Overall, this structure is my favorite part of the entire complex and has the potential for an insane amount of detail to be added. I’ve seen one modelled (insanely well) by Wayne McDade on his HOn3½ layout and it inspired me to do the same.

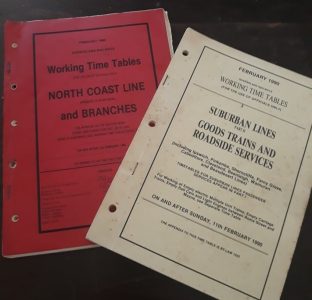

Hopefully, you’ve enjoyed our little series on the Jandowae Grain Complex. It’s something we intend to model in it’s entirety on our next layout. As always though, we shall see how we go.

Hopefully, you’ve enjoyed our little series on the Jandowae Grain Complex. It’s something we intend to model in it’s entirety on our next layout. As always though, we shall see how we go.

We recently reran our popular KSA cattle wagons, Fourth shameless plug

We recently reran our popular KSA cattle wagons, Fourth shameless plug